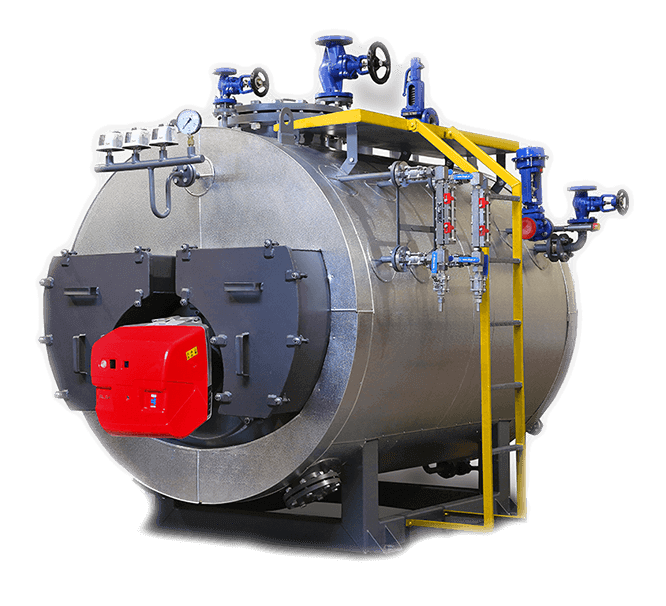

A steam boiler is a type of closed vessel which primary function is to generate large quantities of steam at a very high temperaturę and pressures higher than that characteristic of our atmosphere. The above mentioned steam can be used for heating purposes and , moreover, it is the optimum thermodynamic medium for steam turbines.

The advantages of pressure steam boilers are widely appreciated in many industries, including in particular installations dedicated to the food sector. Examples of companies using this solution include meat and vegetable and fruit processing plants, producers of children’s food, dairies, bakeries, animal waste treatment plants, feed factories and breweries. The production of steam boilers is also often carried out in response to the needs of various agricultural enterprises. The other most common applications related to the food industry also include pasteurization and oil pressing.

Steam boilers in light industry

The specific structure of the boiler, which enables the efficient production of high pressure and hot steam, is also appreciated in the broadly understood light industry. When it comes to applications in this market sector, which are found by heating boilers, Łódź is a perfect example of how many different enterprises can use them. At this point, it is worth noting that, regardless of the branch of the economy, industrial steam boilers used within individual installations always have a very similar general purpose, which, as a rule, in each case is to generate a large amount of water vapor at high temperature and pressure.

Coming back to the applications of boilers in the light industry themselves, these are mainly textile companies such as drying houses, dyeing plants and other plants involved in fabric processing, pantyhose formation or the production of materials dedicated to the manufacture of other garments. The thermodynamic agent in the form of steam generated by the boiler is also used in companies involved in packaging moulding, printing and papermaking. In institutions of this kind it is used, for example, in gluing machines and as part of the equipment present in printing dryers.

Steam boilers in construction

Due to, inter alia, the fact that the construction of the boiler from our company takes into account a number of modern solutions and is based on obtaining energy from gas or diesel, this product is characterised by efficient and economical operation. This feature, in turn, makes it eagerly used also by representatives of the construction industry. The production of boilers intended for the aforementioned market sector is the result of the demand generated by a wide variety of companies, such as those producing polystyrene foam or heating concrete.

Finally, it is worth adding to the list of applications of this described solution in the pharmaceutical industry, where, for example, pastilles are formed using steam boiler-based systems due to the properties provided by the high temperature of the steam- thus, for example, tablets are formed.